Originally published on fastradius.com on July 2, 2020

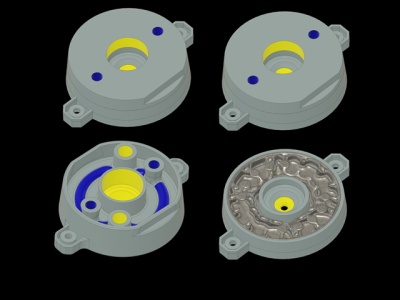

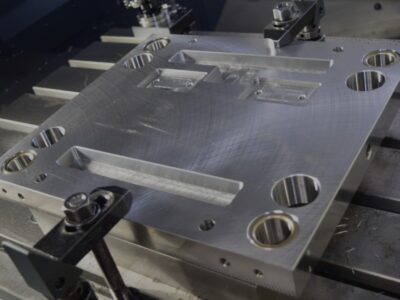

Injection molding is a popular manufacturing process for the mass production of identical plastic parts with good tolerances. During this process, thermoplastic flakes or pellets are melted down and injected into a mold. Once the thermoplastic material cools and hardens, ejector pins pop the completed part out from the mold. Many of the consumer-facing products people use every day are injection-molded, from phone chargers to car parts to Lego® bricks.

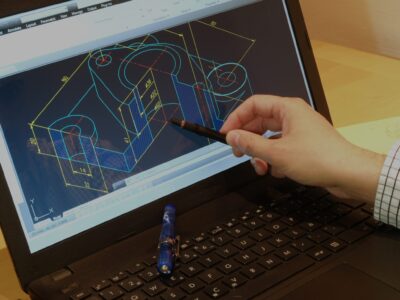

Once the mold is manufactured, engineers have a means by which to consistently reproduce complex parts at a very low cost-per-unit. As such, perfecting the mold-making processes is critical. Here’s a crash course in optimizing the design of an injection molded part — plus tips and tricks for product designers.

Three injection mold design tips and best practices

Injection-molded parts can feature complex geometries, and offer product designers a fair amount of design flexibility. The only caveat is that product teams must design their parts around the specific requirements of injection molding.

It’s very challenging to make design adjustments after the part has already been manufactured. As such, product designers must design the plastic part perfectly for injection molding to reduce the risk of issues with the tool design, achieve the best results, and reduce costs. To design clean, functional parts, start with these three injection molding design best practices:

1. Maintain consistent wall thicknesses

The number one rule of injection molding part design is managing the thickness of the mold. Non-uniform walls can cause the part to warp as the thermoplastic material cools down or cause sink marks to occur. Recommended wall thicknesses vary depending on the plastic used. For example, polyurethane (PUR) has a recommended wall thickness of 0.080 inch to 0.750 inch, while polystyrene (PS) has a much smaller range of 0.035 inch to 0.150 inch. A good rule of thumb is to keep any given mold’s wall thickness between 1.2mm and 3mm.

If the part is designed to include different thicknesses, product designers should make the transition between them as smooth as possible. This ensures that the molten plastic flows evenly inside the mold cavity. A chamfer or fillet that is 3x as long as the difference in thickness should do the trick.

Thick sections in an injection mold design can cause warping, sinking, and other defects, but sometimes they’re necessary for complex geometries. Product designers can include thicker sections in their molds while adhering to wall thickness limitations by hollowing these sections out. Including ribs in the part strengthens the hollow sections and provides stiffness.

Rib thickness varies depending on the thermoplastic used, but ribs should always be less than two thirds of the main wall thickness. If the rib is too thick, it will cause sink marks on the outer surface.

2. Eliminate undercuts that aren’t design critical

Undercuts are features that prevent the injection-molded part from being ejected cleanly from the mold without any structural damage. Undercuts can come in a variety of forms — holes, cavities, or areas where alignment is not perpendicular to the mold’s parting line. A product designer’s best bet is to avoid undercuts altogether. They always make the injection mold design more expensive, complicated, and labor-intensive than necessary.

Still, there are a few design tricks to handle undercuts. The simplest way to fix an undercut is to move the parting line of the mold such that it intersects with the undercut. However, this tip is only applicable for designs with undercuts on the outside of the mold.

Bumpoffs, or stripping undercuts, are an option if the feature and material are flexible enough to expand and deform over the mold during ejection. The bumpoff should be far away from the mold’s support structures and have a lead angle between 30 to 45 degrees.

As a last resort, side-actions or lifters can fix undercuts when the mold cannot be redesigned to avoid undercuts. Side action cores are perpendicular inserts that slide in and out of the mold as it opens and closes.These mechanisms drive up cost and complexity significantly. Even with these solutions, it would behoove designers to steer clear of undercuts altogether and eliminate undercuts during prototyping.

3. Draft, draft, draft

Draft angles are design considerations that make it easier to cleanly eject an injection-molded part from the mold. This might sound like a non-essential design feature, but drafts are critical to manufacturing functional injection-molded parts. Drafts help prevent the part from becoming damaged upon release, lower production costs, accelerate production timelines, ensure a uniform surface finish, and provide a slew of other benefits. Without draft angles, product teams risk damaging their expensive molds and producing a large number of rejectable parts.

Drafts should be accounted for early in the design process. Draft angles will vary according to a number of factors related to the part, including wall thickness, wall depth, material, and any applicable shrink rates, texture, or ejection requirements. It’s best to apply as much draft angle as possible. Product designers should include one degree of draft per inch of cavity depth to start, adjusting for the aforementioned factors as necessary.

Even if it looks like draft might negatively impact the performance of the part, it’s always better to have draft than to not have draft. Parts can be designed with a minimum of 0.25 degrees of draft, generally, but the smallest degree of draft possible will depend on the part’s unique geometry and material.

Get help from the design experts

This short list only scratches the surface of key design considerations for injection-molded parts. Product teams must also consider factors including parting lines, gate design, gate location, and more. The best way to optimize part designs for cost-effectiveness, production time, and efficiency is to partner with a manufacturing expert who can offer crucial advice throughout the design process.

The design and engineering experts at SyBridge Technologies can help you work through common mold design pain points, re-optimize current designs, or create something totally new. We can help cut your development cycle by up to 90% and accelerate your time to market on any product. Let’s make new things possible — contact us today.