Originally published on fastradius.com on May 31, 2022

Injection molding is the most popular mass production method when creating large volumes of identical plastic parts — and for good reason. While you may need to invest a significant amount of money upfront to manufacture injection mold tooling, your price per unit will be extremely low if you produce parts en masse and will continue to drop as you make more pieces.

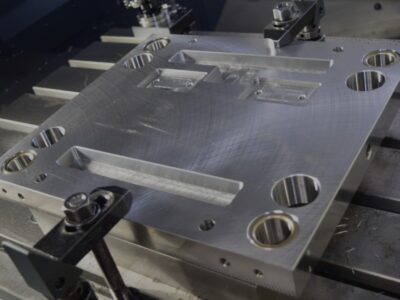

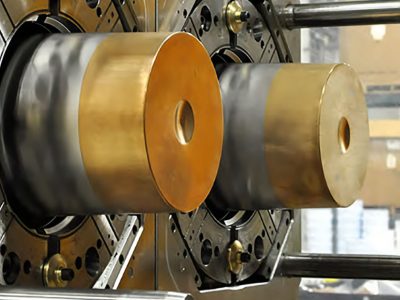

A complete injection mold system consists of a mold base and one or more sets of core and cavity inserts — these inserts are the primary components that mold your part. However, you may also see the more general term “mold” being used, which typically refers to the combination of the core and cavity insert pair.

For previously produced products, existing injection molds will suit any new production runs just fine, so you can continue to use the same mold and reduce your cost per unit. Well-constructed and plated molds can last for up to one million shots. However, if you need to alter your design, change your material, or resize your product, you may not be able to continue using your current setup. Luckily, that doesn’t necessarily mean you’ll need to create a brand new injection mold. In some cases, modifying your existing mold to better suit your needs makes more sense. Here’s what you need to know to make the best decision for your project.

Does making a new injection mold cost more than modifying an existing injection mold?

In many cases, both new and modified injection molds can get the job done. However, the cost of creating a new injection mold is notoriously high. Simple tooling for a low-volume production run can cost anywhere from $2,000 to $5,000, but tooling for full-scale production of a large, complex part can be far more expensive. Depending on the size, complexity, number of cavities, and mold material, you may pay tens of thousands of dollars — or even over $100,000.

Significant design changes can be expensive due to the high cost and lengthy lead times associated with creating injection mold tooling. Not only will you likely need to invest thousands of dollars into creating a new mold every time you alter your design, but you may also need to wait five to seven weeks (or much longer for complex mold systems) for the new tooling to be manufactured. Without a doubt, this could negatively affect your revenue and impact your customers.

Given the complexities of producing and assembling a new injection mold, modifying an existing injection mold may save you time and money in the long run.

When should you modify an existing injection mold?

Creating brand new tooling from scratch requires a lot of time and money, but the good news is that — in some cases — you can modify an existing mold. You may be able to modify an existing mold if you’re:

- Increasing the size, shape, or wall thickness of your final product.

While it’s potentially costly to reliably add metal to the inside of your mold, it’s possible to incrementally reduce the amount of metal inside your mold to expand your final product’s size or increase its wall thickness. However, you should perform a mold flow analysis on the new design to determine the risk for potential sinks. - Adding a small part or feature.

If you have enough room in your tooling and use well-designed inserts that precisely fit into the core and cavity details, you can add a small part or feature to an existing mold.

However, you should consult with your engineering team if your mold inserts are polished and/or plated, there are numerous side actions with precise timing, or there are numerous interchangeable inserts. These features need to be evaluated if design changes are being considered.

If you believe you might modify your injection mold in the future, make sure to inform your manufacturer at the onset of the mold creation process to save yourself time and money in the long run.

When should you make a new injection mold?

Despite the time and money associated with creating a new injection mold from scratch, there are some situations where it isn’t possible to alter an existing mold and achieve your desired results. You may need to manufacture a new injection mold if you:

- Need to reduce the size or shape of your product.

Since it’s potentially costly to reliably add metal to an existing mold, if your part needs to be reduced in size or shape, you may need to manufacture a new set of mold inserts. - Plan to change materials.

If you need to substitute one material for another due to supply shortages, or you realize your chosen material isn’t suitable for its end-use or environment, you may need to create a new cavity and core set, assuming the molded part is out of your tolerance range. After all, each material has its own shrinkage property, and if your new material doesn’t shrink as much as your old material did, you’ll need to build a smaller mold to accommodate its shrinkage. - Need to modify the parting line.

Making changes to the parting line can affect your mold’s vents and gates, so most modifications or additions to your parting line will require a new set of injection mold inserts.

Injection molding with SyBridge

Choosing whether to modify your injection mold or build a new one from scratch is a big decision that can impact your business and your customers, so it’s important to understand the benefits and drawbacks of each option.

While some redesigns are unavoidable, our experts can help you avoid the common design mistakes behind many mold alterations, saving you time and money. We can help you through the design, testing, and production phases, and offer guidance when it comes to modifying an injection mold or building a new mold. Upload your part to start your next injection molding project today, or contact us to see how we can help fulfill your injection molding needs.