Originally published on fastradius.com on October 23, 2019

Cyanate Ester (CE 221) is an additive material developed by Carbon ®. Designed for their digital light synthesis (DLS) process, CE 221 is known for its high temperature resistance and rigidness. Because of its high heat-deflection it can be used in applications with extreme thermal requirements. It is also important to note that CE 221 is comparable to glass-filled nylon and is best suited for under-the-hood components, electronics assemblies, and industrial products.

Mechanical Specifications

Because of its incredible stiffness, strength, and temperature resistance, this high-performance material is perfect for tough environments. Take a look at some of CE 221’s key mechanical properties:

- Ultimate tensile strength: 92 ± 13 MPa

- Elongation at break: 3 ± 0.8%

- Flexural modulus: 3 ± 0.8%

- Flexural strength: 131 ± 27 MPa

- Heat deflection temperature: 231 °C

Read the Carbon CE 221 datasheet for more information.

Why CE 221?

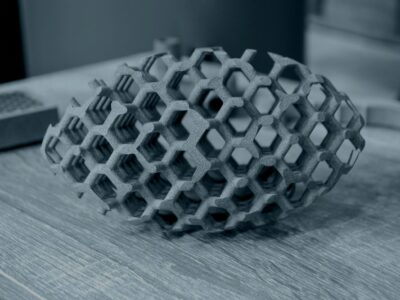

CE 221’s chemical and temperature resistance make it the perfect plastic when intense heat is required. Most plastics will deform in high-temperature environments, but CE 221 will remain rigid. This additive material can withstand high pressure and is fluid compatible. Combined with Carbon’s CLIP technology, CE 221 also provides precision-level surface finish and behaves similarly to 14% glass-filled Nylon 6.

Popular Applications

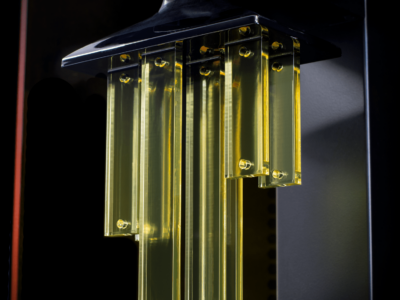

CE 221’s heat deflection properties and ability to withstand large amounts of pressure, make it the perfect material for applications that require thermal and chemical stability. Industrial products, electronic assemblies, and under-the-hood components can benefit greatly from CE 221. Current industrial grade end use parts using CE 221 include fluid manifolds, cooling modules, and microfluidic applications.

Getting Started With CE 221

SyBridge thrives on making new things possible. Our highly qualified team of engineers can help optimize your next application. Talk to our team today about lead times, or any other considerations you may have.