Originally published on fastradius.com on December 21, 2020

Prototyping is an integral stage of the production lifecycle that helps designers and engineers ensure that their part designs are fully validated and optimized before manufacturing begins. Prototypes and mock-ups can be used to demonstrate proof-of-concept or to test specific material or performance characteristics.

Regardless of application, prototyping can shorten the design cycle, optimize parts for end-use functionality, help product development teams anticipate challenges before they cause costly redesigns, and find cost-cutting opportunities. Ultimately, prototyping makes production more efficient and cost-effective.

New technologies are refining the prototyping process. Additive manufacturing, or 3D printing, for instance, has led to the development of rapid prototyping, which enables engineers and production teams to create accurate, functional parts faster and more economically than ever before.

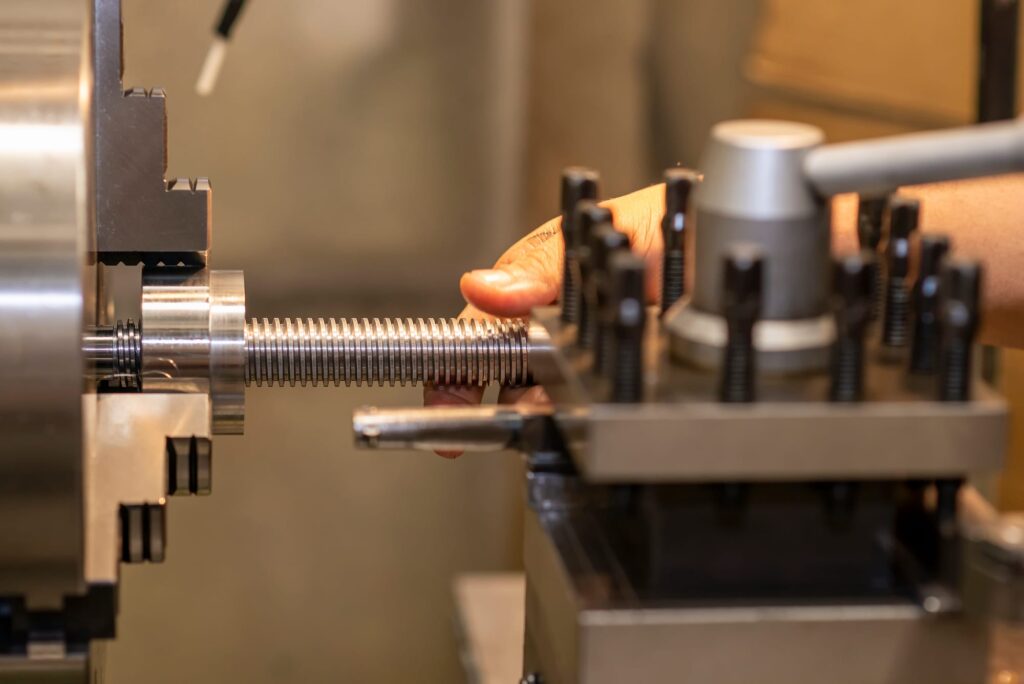

While 3D printing is becoming more common for rapid prototyping, CNC machining is still a popular option. With a wide variety of materials capable of withstanding extreme environments, machining prototypes can be useful.

Here are a few prototyping best practices for CNC machining.

Keep Prototypes Simple

Because metals can withstand much higher temperatures and pressures than plastic, machined metals are used to create the molds and tooling used in injection molding and die-casting. One primary way to keep machining costs low is to streamline prototype designs.

Draft, for instance, is vital to ensuring that die-cast and injection-molded parts can be ejected from their molds without damage. However, draft requires complex, time-consuming machining, which may not be necessary or an economical use of resources during the prototyping stage.

Furthermore, features like angles and undercuts require multiple setups or specialized tooling, both of which can significantly increase the development time and cost of production for prototypes. Before submitting a prototype, consider which features are absolutely necessary to see during development, and which will just increase cost.

Design With Tool Geometry in Mind

Rotation is a core element of how CNC machining operations function, and the axial qualities of the cutting tools or the workpiece must be factored into prototype CNC machining.

Most cutting tools are cylindrical and have a limited cutting length, which means that all cutting operations will bear the shape of the tool. Internal corners and other features will therefore have a radius, with larger radii leading to faster machine times.

Internal features may also require additional or more complex machining if the design of the cutting tools is not considered in the design of the part. For example, if the team wanted to verify that the external mating features of a part were designed correctly, they would forgo machining the internal features and just machine the outside. CNC lathe rapid prototyping — which involves rotating the workpiece but not the cutting tools — is excellent for screws and doorknobs, but not well-suited for parts that are not axisymmetric.

Use Default Tolerances

Tighter tolerances may require a combination of specialized cutting tools, detailed machining, or additional jigs and fixtures to achieve. If tighter tolerances are needed, the prototype can be used to show the true cost of reaching these restrictions. This could lead the team to review the tolerance stack up to see if loosening is an option.

Increase Order Volume

Because of the setup involved, CNC machining is typically not used for low volume orders, as the per-unit cost can be quite high. This creates a potential problem for teams looking to machine CNC plastic prototypes or metal prototypes. However, one strategy is to see how quotes change when prototype orders increase by an additional few pieces. Quite often, an increase in production volume drastically cuts per-unit prices without generating significant overhead.

Prototype With a Seasoned Manufacturing Partner

Prototyping is a crucial step in the production lifecycle that helps to ensure part designs are fully optimized before manufacturing begins. CNC machining can be a highly efficient method of rapid prototyping, so long as product teams attend to the unique geometric demands of the machining process and work to ensure operations are streamlined.

SyBridge has built one of the world’s leading on-demand manufacturing businesses upon industry know-how like the best practices listed here. Our team of talented designers, engineers, machinists, and technologists brings decades of expertise to every project, offering end-to-end support throughout the production lifecycle. We work hard to develop better, more efficient solutions for modern manufacturing problems — which our customers see reflected in the quality and consistency of their parts. Contact us today to learn more.