Originally published on fastradius.com on October 5, 2020

The term “resin” can refer to both solids and liquids, but most often refers to liquids that harden with the application of heat, light, or setting agents. Flexible Resin is part of a subset of resins made by Formlabs that are relatively soft and malleable.

While some resins lack stiffness due to environmental conditions or improper post-processing, others are meant to be flexible — Formlabs’ Flexible Resin falls into this category. These resins are typically used for stereolithography (SLA), a 3D printing process in which a high-powered laser hardens liquid resin layer-by-layer to create the desired 3D shape.

Properties and mechanical specifications of Flexible Resin

Flexible Resin is rubber-like, with distinct elastomeric properties but relatively low elongation. In other words, these resins can be bent, compressed, and stretched slightly. After this type of deformation, they’ll return to their original shape or size. Because they’re flexible, they cannot shatter, but they can tear if subjected to sufficient pressure.

In general, Flexible Resin is more pliable when laid thinly, and less flexible when thick. Parts made with Flexible Resin that need to be durable should have thicker walls.

Another key consideration of Flexible Resin is the finishing stage. Parts must be slowly and carefully peeled off of the print bed and then washed in an IPA finishing solution. Flexible Resin also requires post-curing to reach its optimal mechanical properties.

Formlabs has produced a few different variations of Flexible Resin, whose respective mechanical specifications include the following:

Formlabs Flexible 80A Resin: 80A Resin, is Formlabs’ newest version of Flexible Resin. It’s a very high-viscosity resin and its cured state is exceptionally strong. Some of its mechanical properties include:

- Elongation at break: 120%

- Tensile strength (MPa): 8.9

- Shore hardness: 80A

- Tear strength: 24 kN/m

Formlabs Flexible 1 L Resin: This resin is a legacy formulation of the Formlabs 80A resin, but it’s still available for purchase until March 2021, when it will be completely phased out. Some of its mechanical properties include:

- Elongation at break: 80%

- Tensile strength (MPa): 7.7-8.5

- Shore hardness: 80-85A

- Tear strength: 10.6

Formlabs Elastic 50A Resin 1 L: Formlabs 50A Resin is a particularly soft, flexible resin, and it’s considered suitable as a replacement for silicone. It’s technically classified as an Elastic Resin, but should be considered as a potentially suitable material when manufacturing with Flexible Resin. Some of its mechanical properties include:

- Elongation at break: 160%

- Tensile strength (MPa): 3.2

- Shore hardness: 50A

- Tear strength: 19.1

Why Flexible Resin?

The defining properties of Flexible Resin — its elasticity, malleability, and low elongation — make it an extremely versatile material. It is considered an ideal material for high-impact applications.. It can be employed at any phase of the production process, from ergonomic and functional prototyping to market-ready parts, though it’s most often used for prototypes.

Popular applications of Flexible Resin

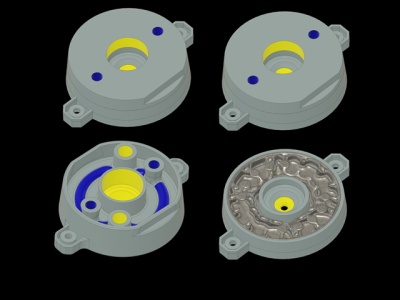

While most commonly used for prototyping, Flexible Resin has a range of other common applications. The material tends to be suitable for high-impact applications such as grips and holds, cushioning, and gaskets. Shoe insoles, for example, are often made with Flexible Resin. However, it’s not considered suitable for applications that require a stretchy material, nor is it suitable for applications that require especially fine detail.

It’s also suitable for detailed prints, as long as the prints aren’t especially fine. Because of its resilience, durability, and flexibility, it is used in parts that must withstand a high impact or that need to be soft-touch; seals and gaskets, wearables and other consumer products, medical devices, props, and modelmaking are all suitable applications for Flexible Resin.

Getting started with Flexible Resin

Flexible Resin is an incredibly versatile and sturdy material that can be used effectively in a wide range of applications to offer both durability and flexibility. However, because of its elastomeric properties, it’s not ideal for long, thin, or especially fine-detailed parts. It’s essential that product teams do their research to determine what kind of resin is best-suited for their part and their unique requirements.

SyBridge is an on-demand digital manufacturer offering both traditional and additive manufacturing services, and our experience working with a range of materials — including both traditional resins and Flexible Resin — makes us an invaluable partner for product teams across the globe.

Our team of experienced designers and engineers provide our customers with robust support throughout every stage of the production process — from design, to material selection, to bringing a product to market. Contact us today to learn more about how we can help your team utilize Flexible Resin.