Originally published on fastradius.com on July 7, 2021

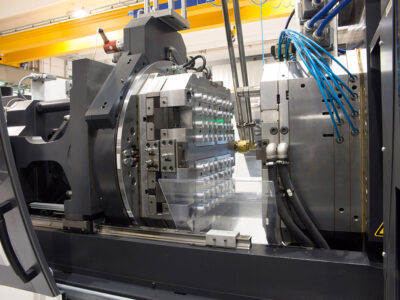

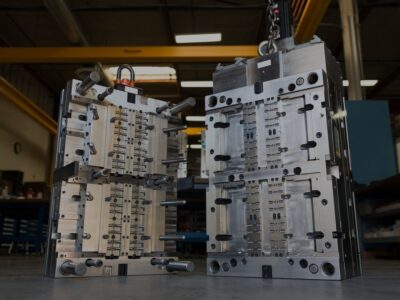

Injection molding is a manufacturing process that enables you to quickly and consistently produce uniform parts at low costs. During the injection molding process, a highly pressurized nozzle fills a mold with molten material, which then cools and hardens in the mold. Afterward, the mold opens and the injection-molded part is safely ejected.

On its own, injection molding is a fast and efficient manufacturing process that is excellent for high-volume production runs of uniform, intricate parts. When combined with automation, product teams can take injection-molded components and procedures to the next level. Here’s everything you need to know about automation in the injection molding process.

An overview of automation in injection molding

Automated tools are used throughout manufacturing to increase the efficiency, speed, and precision at which tasks are completed. Some automation tools like collaborative robots (cobots) and robotic arms assist workers with their operations, while other automation tools complete tasks entirely on their own. Intelligent automation in manufacturing keeps engineers and machine operators safe during high volume, stress-heavy manufacturing processes.

Automation tools in the injection molding process also help ensure parts are properly made, accurately measured, and formed to completion. Manual injection molding usually yields natural variations, which can result in poorly built or non-functional components. By maintaining precision and handling fragile parts delicately, automation in injection molding can prevent cosmetic and structural defects. Also, many automated tools have built-in features that prevent damage to the injection molding machine.

Here are some specific ways automation tools can improve the injection molding process:

Machine tending

This includes standard procedures like heating up the injected material, pressurizing the molten material so it fills a cavity entirely, and ejecting a cooled part without damaging it.

Insert molding

Inserts increase the strength of a plastic injection-molded part. Automated tools can safely and precisely add inserts at various stages in the injection molding process.

Overmolding

Overmolding techniques are used to combine two parts together. Automation tools can safely move injection molded parts between machines in order to quickly perform these processes.

Handling post-processing tasks

This includes trimming away a part’s excess material, dispensing sealant or finishes evenly, and performing post-process quality checks. Automated tools can even assist with packaging and fulfillment, like sealing parts for shipment or moving them into containers.

Clean-up

Automated tools can clean up after an injection mold job by removing leftover solid material from various parts of the injection molding machine. This expedites clean-up and facilitates easy recycling, particularly with plastic injection molding. Also, the use of automation during the injection molding process produces less waste overall.

These are just a few examples of how automation in injection molding can speed up production times, improve part quality, and increase safety during the manufacturing process.

Benefits of automation tools in injection molding

It’s incredibly beneficial to work with a manufacturing partner that uses automated processes for injection molding. Automated tools lower manufacturing costs for high-volume production runs, which means lower costs for you and your business. Also, automated tools dramatically speed up production times so you can get better products to market faster.

Automated tools also improve the accuracy and repeatability of individual components, which ensures consistency part-to-part and improves the overall quality of your production run. With automation, you’re less likely to have to go back and fix bad batches. Reducing inconsistencies also reduces material waste, which in turn increases material cost savings.

Automate your injection molding projects with SyBridge

Automation improves the injection molding process by making it easier to safely and accurately perform operations that ensure part consistency, precision, and functionality. It’s important for product teams to work with a manufacturing partner that uses the power of injection molding automation to make the best parts possible.

At SyBridge, we have the tools and expertise to help you create superior parts, reduce costs, expedite production runs, and reduce errors during the manufacturing process. If you have any questions or concerns, our team of experts will guide you through them. Contact us to get started.